In This Story

- Inefficient pumps silently steal from utility budgets

- Data reveals clues that pumps won’t confess

- Digital tools turn waste into savings

Pumps and the systems they interact with are complicated, so there are many ways they could be wasting energy. The offending pump won’t tap you on the shoulder as you walk by and say, “Stop me before I steal again.” Utilizing advancements in technology and further developments in water digitization (read Tom’s full breakdown here), solutions are emerging.

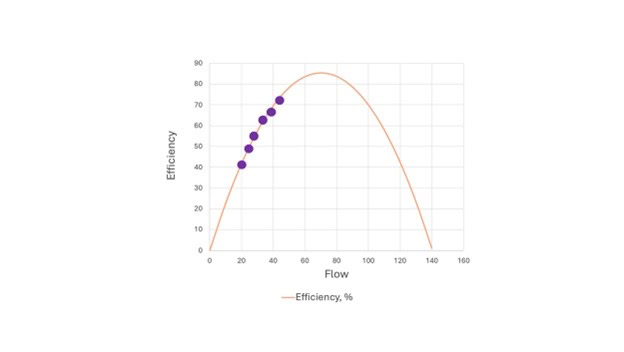

So put on your detective badge and start investigating. Inefficient pumps are pretty sloppy, and they leave clues. Centrifugal pumps do not put out a constant outflow—their output can vary as operating conditions change over time, sometimes even minute to minute. When the pump was new, this relationship was known and could be represented as a pump efficiency curve. (Efficiency curves are one of four curves that characterize pump performance.) Ideally, you want to be running at the highest point on the pump efficiency curve, which is called the Best Efficiency Point. That’s the blue point on the curve.

Pumps and the systems they interact with are complicated, so there are many ways they could be wasting energy. The offending pump won’t tap you on the shoulder as you walk by and say, “Stop me before I steal again.” Utilizing advancements in technology and further developments in water digitization (read Tom’s full breakdown here), solutions are emerging.

So put on your detective badge and start investigating. Inefficient pumps are pretty sloppy, and they leave clues. Centrifugal pumps do not put out a constant outflow—their output can vary as operating conditions change over time, sometimes even minute to minute. When the pump was new, this relationship was known and could be represented as a pump efficiency curve. (Efficiency curves are one of four curves that characterize pump performance.) Ideally, you want to be running at the highest point on the pump efficiency curve, which is called the Best Efficiency Point. That’s the blue point on the curve.

But flow changes over time due to varying demands, tank water level fluctuations, piping changes, and valve settings.

The curves themselves can also change due to wear, poor tolerance adjustment, and bearing failure, among other things.

Interpreting Your Clues

To identify the bad pumps, you can wait until the pump makes horrible sounds or appears to want to vibrate itself to death. But by then, you’ve already wasted a ton of money. You need data, which you can find in your SCADA System (Supervisory Control and Data Acquisition) or in other Internet of Things (IoT) devices. This data is stored in your historian, a piece of software that collects and stores data about pressures, flow rates, and other information.

First look for spots where the pumps no longer perform on their pump curves. Discrepancies between the curves and the actual pump data typically reveal problems with the pumps themselves. If you’re lucky, a mechanic can correct these problems in an hour. But the issues may require major rehabilitation of the pump, or they may even be a sign that the pump is ready for the junkyard (or an antique museum). To identify problems, look for pump data that doesn’t fall on the expected curves. Those are the purple points below.

Even if a pump is operating on its desired curve, you may still find problems when it isn’t operating near its best efficiency point. The actual operating point depends not only on the pump, but on the entire system. And there are numerous possible reasons for the problem: The engineer who selected the pump may have made inaccurate assumptions about future development in the service area. Pipe sizes and the elevation of water tanks may have not panned out. Operational problems, such as an operator simply closing a valve that should be open. A pair of pumps that just don’t play nice together. Or air collecting at a high point where an air release valve should have been installed to keep the air bubble from clogging the pipe. (In wastewater systems, the “air” is actually a nasty mixture of gasses.)

The pump data below shows a pump that is operating on its cure but not at a good point.

But that’s not enough complexity; consider that the problems differ depending on whether the pumps are discharging into an open or closed system. An open system would have an elevated water tank for a water system, or a manhole in the case of a wastewater system. A closed system has no such free surface and is more difficult because its pump or pumps must continuously meet instantaneous demands. Open systems can rely on tanks and wet wells to dampen out fluctuations.

If there is a problem, you may face a critical decision: Replace the pump? Repair it? Or monitor it? The answer comes down to the life cycle costs for the pumps, which include equipment and labor. But the largest cost item is energy—and unfortunately, energy cost is the most difficult to accurately calculate.

In the past, calculating the energy cost of pumps over time was a tedious and challenging process. This led to shortcuts and assumptions that reduced the accuracy of cost estimates. With the advent of digitalization, computers have relieved engineers of the tediousness of this work.

Calculating Energy Costs

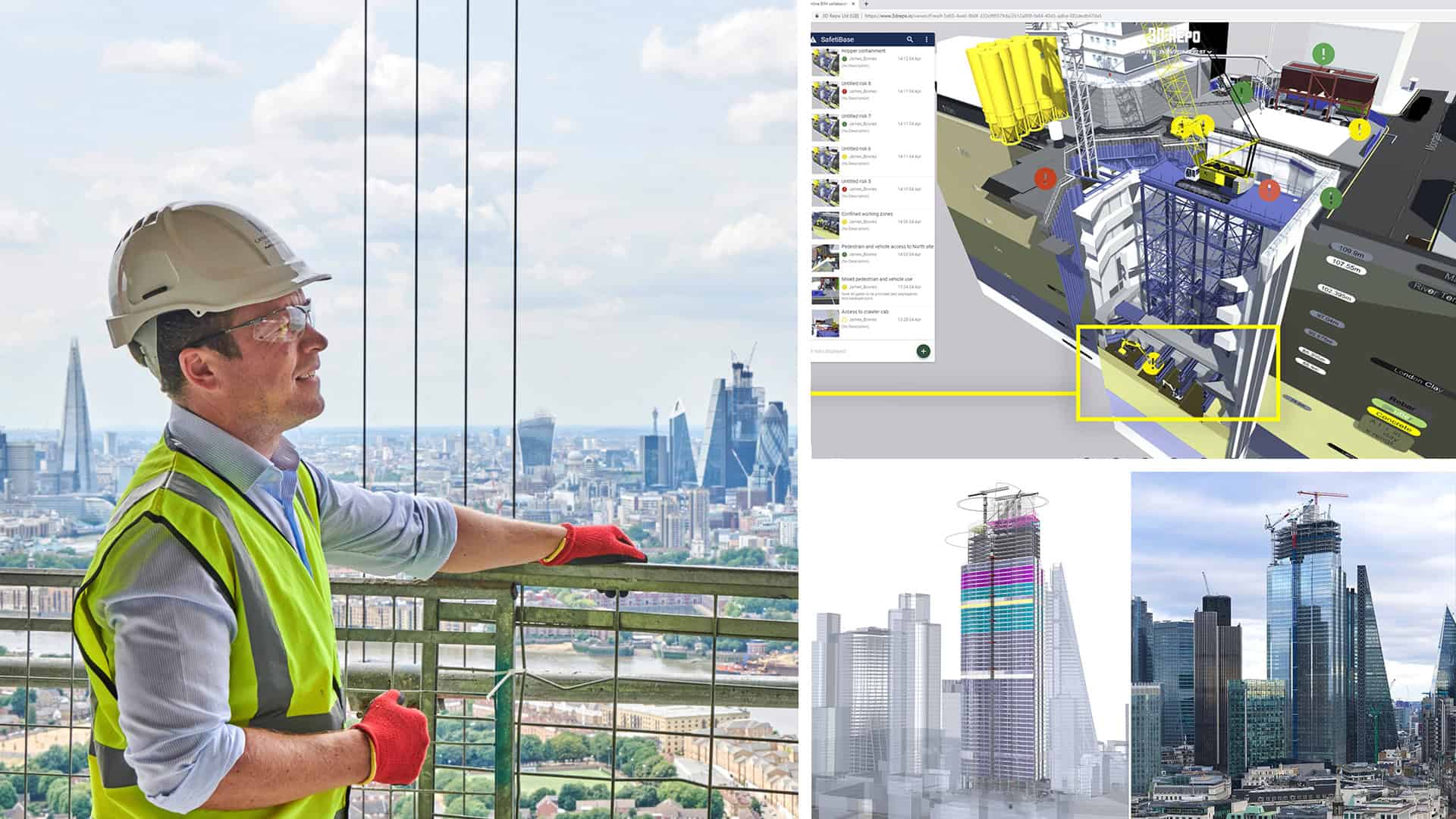

The friendly equation below underlies the cost calculation. Don’t worry, you don’t need to manually solve the equation (unless you feel like it) because software like Bentley Systems’ OpenFlows Water and WaterSight can do it in a few mouse clicks.

Where C = cost of energy over some time T, Q = flow, h = pump head, p = unit price of energy, γ = specific weight of water, ep = efficiency of pump, em = efficiency of motor, ed efficiency of drives k = unit conversion factor.

Clues for Energy Saving

The terms in the equation provide some tips for reducing energy cost. You want to reduce the terms in the numerator (the top of the fraction) and increase the terms in the denominator. To reduce Q, you want to reduce demands by water conservation, leak reduction, or possibly reorganizing pressure zone boundaries to ensure you aren’t over-pressuring neighborhoods. To reduce H, you can use bigger pipes, open throttle valves, eliminate air blockage, clean rough or blocked pipes, avoid inefficient pump combinations, or lower the water level in proposed tanks. Each of these remedial measures has a cost that needs to be compared with the energy savings it produces. (You can’t do much to control the specific weight of water. Even the best software can’t make water lighter.)

In the denominator, correct pump selection and operation can keep the pump operating near its best efficiency point. Motor efficiency can be improved by using high and premium efficiency motors (at a cost). The efficiency of a variable speed drive (if you use one) depends on how it’s programmed.

Actual Energy Price

It’s possible to reduce energy use but have minimal or negative effects on energy costs. This is where the unit price of energy comes in. Calculating the cost of energy is not as simple as calculating your water bill, which is usually just quantity used multiplied by unit price of water (gallons times dollar per gallon). There are many factors that affect energy pricing, such as time-of-day pricing, seasonal pricing, block rate pricing, and demand charges.

For large power users, pricing is spelled out in a tariff document that contains the rules governing the account. Much of a tariff document is written by lawyers for lawyers, but the documents include a page that spells out pricing. Somebody in the utility has it in their files. If you can’t find it, the power company will be happy to send you a copy.

The tariff gives you clues as to how you can save money. For example, if the price of energy increases between 2 p.m. and 6 p.m. on weekdays in the summer, you need to reduce your pumping during that time by making sure your tanks are relatively full at 2 p.m. so you can minimize pumping. Unlike water utilities, which can store water (and its associated energy in tanks), power companies need to meet instantaneous peak demands. They must size their infrastructure to meet those peaks. One strategy is to make users pay more for energy during peak times.

These charges, which can vary widely among power companies, are based on some measure of peak power demand, such as the peak hourly demand during the air conditioning season, or the peak 15-minute demand between and 2 p.m. and 6 p.m. The problem with these charges is that once they are established, they stay on the bill for multiple billing periods unless they are exceeded.

It’s important to understand the situation that resulted in the peak demand you’re paying for. Was it a major pipe break, a questionable operator decision, or maybe a large fire? (Fire fighters have other things on their mind beside saving energy.)

Clues from your energy bill

Have you ever looked over your energy bill? Find it and review it. Usually somebody in the accounting department has it. In many cases, when the energy bill comes in, someone in accounts payable looks it over and, as long as it’s within budget, pays it. The operators and engineers who can affect these costs may seldom, if ever, review them.

Modern hydraulic analysis software can calculate what the bill should be. If there are differences between the bill and the model, the source of those differences needs to be investigated. They may be due to poor decisions on when to turn pumps on and off or running incompatible pumps at the same time. Maybe the model isn’t reflecting the way that operators really make decisions. These differences need to be diagnosed and resolved.

Realizing (or not) Energy Cost Savings

Walking into a pump station is a bit like walking into a gold mine. Little nuggets of energy gold are usually lying just below the surface. You just need to do some digging to find them.

If looking for energy saving is such a huge opportunity, why don’t utilities spend more resources looking for savings? Part of the problem is that no one gets fined for wasting energy. The power company is very willing to take your money.

Utilities are very interested in saving energy and money. Someone is usually tasked with achieving those savings. If after several months, you ask the individual how their energy study is going, the response may be something like, “I started working on it. But I got pulled off to buy those new chlorinators, then I had to prepare the briefing for the mayor, and I needed to hire a contractor to repaint the South Street Tank.” Meanwhile, money that could have gone to other beneficial uses goes out the door.

Energy study tools now make it easier to perform an energy-savings analysis. If you look for energy savings, you’ll find them.

Read more of Tom’s blogs here, and you can contact him at [email protected].

Want to learn more from our resident water and wastewater expert? Join the Dr. Tom Walski Newsletter today!