From reactive to proactive maintenance

Most plant operations rely on dashboards and logs, which provides much-needed structure. But behind the scenes, they often create a false sense of control. Often, there are unknown factors at play that don’t show up in reports. What plants really need are digital tools to provide improved data insights to help operators gain more control and predictability of plants and drive smarter maintenance strategies.

Sitech, a company that helps chemical and production plants be more productive and efficient, faced major challenges with their clients’ asset performance management strategy. These challenges included the increase in equipment failures and the expensive, and hazardous maintenance of 200 time-based assets. If unchecked, these issues could cost money, jeopardize worker safety, and harm the environment.

Bringing risk-based inspections alive

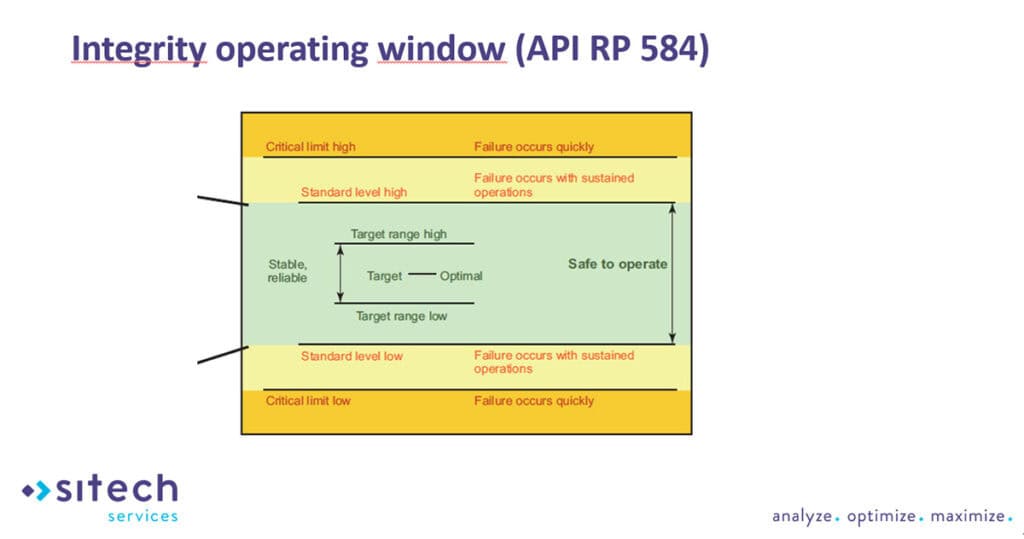

To tackle these challenges, Sitech turned to risk-based inspections (RBI), a smarter maintenance plan. They brought this plan to life by leveraging decades of engineering experience and adopting the APM AssetWise solution from Bentley.

To create their plan, Sitech analyzed the risks to their equipment and assessed the likelihood of failure by using historic inspection data. By working smarter with real-time data from sensors, they identified problems early, enabling them to easily adjust the plan and create a feedback system for continued improvement. All information is now stored and tracked in the APM AssetWise system, establishing continuous monitoring of the health and lifespan of each asset.

How Sitech reduced costs and environmental impact

By adopting the smart RBI digital strategy, Sitech saw significant improvements in safety, costs, and environmental impact.

This strategy provided confidence in a safer workforce by checking equipment remotely and using non-destructive methods. It helped lower costs—one piece of equipment would cost approximately EUR 126,000 every 6 years to maintain. With the new strategy plan, it now costs only EUR 19,000. The plan established greener operations requiring less cleaning and waste, resulting in reduced harm to the environment. And with a smarter system, all of Sitech’s expert knowledge is now retained in a platform that can be used repeatedly.

A scalable model for the future

Thanks to Bentley’s technology and Sitech’s vision, this successful digital and sustainable approach will be replicated across 200 assets at several of their customer sites and transform plants for a greener future.

Discover how AssetWise supports safer and smarter plant operations by visiting the product page, where you can learn more and connect with an expert or read the case study here ❯