I traveled to the U.S. in November to meet my team at Bentley Systems headquarters just outside Philadelphia. I am a senior product marketing manager in Europe at Bentley, the infrastructure engineering software company, and I specialize in software for building and maintaining bridges.

I am a curious person, so while away from my home in Romania, I decided to explore Philadelphia. I love infrastructure and, naturally, I was drawn to the city’s bridges. Walking around, I couldn’t help but notice the ongoing repair work on aging bridges around the city. One afternoon, as I walked beneath the rusted steel beams of an 80-year-old bridge, I watched a team of inspectors at work. It was fascinating: They hung from safety harnesses, taking photos, writing notes on clipboards, and occasionally tapping spots they deemed suspicious with hammers. It’s the same inspection routine bridge engineers have used for decades. “We’ll be lucky to finish three bridges this week,” said one of the inspectors. “And we’ve got 43 more on our list before winter hits.”

This is hard and important work. Across the U.S., over 220,000 bridges desperately need major repairs or full replacement. I chatted with the inspectors about Bentley’s software and other digital solutions that can make their jobs faster, more efficient, and easier. Our software can ingest photogrammetry data from drones surveying bridges and other infrastructure, create their virtual replicas as digital twins, analyze the models, and highlight sections that need closer inspection. Inspired by the conversation, I summarized my thoughts and created a list of bridge projects around the world that have already benefited from our digital technologies. Here are the highlights:

Closing the Digital Loop

Let me tell you about what makes me most excited about my work at Bentley. Our digital solution improve every stage of the asset life cycle, from design to construction to maintenance. The solutions, which include digital twins, AI-powered bridge inspections and predictive maintenance using data from the Internet of Things (IoT), ensure that bridges are not only designed and built better but also monitored and maintained more efficiently. They’re cutting inspection time, reducing costly delays, and preventing disruptions to the public.

How? Engineers use our software to create digital twins of their projects—there are even digital twins of entire cities! These real-time, interactive models of bridges and other infrastructure improve design accuracy and predictive maintenance. Bentley’s geotechnical data analysis also allows engineers to assess subsurface conditions, ensuring that bridges are built on stable foundations. We also provide AI-driven asset analytics to predict wear and tear, which helps engineers prioritize maintenance and reduce emergency repairs. And I already mentioned the IoT. Sensor monitoring bridges connected to the IoT allow teams to track structural performance and detect problems before they become major failures. Our 3D geospatial visualizations also provide high-resolution, interactive environments and improve collaboration and project planning.

Here are a few ways Bentley’s digital solutions are making a difference. These real-world case studies highlight a fundamental shift in the way bridges are designed, inspected, monitored, and maintained. By leveraging digital twins, AI-powered inspections, and IoT-driven bridge monitoring, agencies and engineering firms are achieving:

- 20-30% reductions in bridge inspection labor costs

- 10-15% savings on infrastructure repair costs through preventative maintenance

- Faster inspections and more accurate repair planning using AI and IoT analytics

- Fewer costly delays and reduced disruptions to the public

Building Bridges to the Future

A bridge’s longevity and resilience are largely determined during its design phase. A well-designed bridge incorporates predictive maintenance insights from the start, reducing the need for costly retrofits and unplanned repairs in the future. Early geotechnical data analysis can help ensure that bridges are built with appropriate, durable materials that extend their lifespan while minimizing environmental impact. Plus, parametric 3D modeling, which allows users to create data-driven designs and digital twins, helps engineers anticipate construction challenges before they arise and deliver their work on time and on budget.

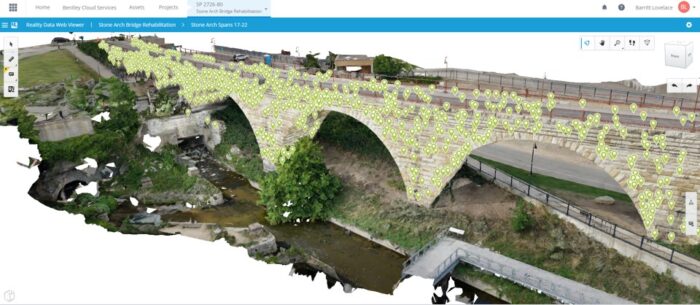

Digital twin of the Stone Arch Bridge. Image courtesy of Collins Engineering.

Digital twin of the Stone Arch Bridge. Image courtesy of Collins Engineering.Collins Engineers’ work on the Stone Arch Bridge rehabilitation in Minneapolis demonstrates the ability of AI-powered bridge inspection technology in modern infrastructure projects. By implementing a digital twin for bridge asset management, Collins Engineers reduced inspection time by 20%. The team also minimized disruption by limiting the bridge closure to just four days instead of weeks. Their innovative approach also contributed to cost savings of 10-15% for the Minnesota Department of Transportation. By integrating AI-driven asset analytics, engineers could pinpoint repair needs with precision, reducing unnecessary work and optimizing resource allocation.

Digital Innovation Transforms Historic Bridge Inspection

Robert Street Bridge shown highlighted with digital road markings after an inspection. Image courtesy of Collins Engineering.

Robert Street Bridge shown highlighted with digital road markings after an inspection. Image courtesy of Collins Engineering.Collins Engineers also revolutionized bridge inspection by implementing Bentley’s iTwin Capture and iTwin Experience for the iconic Robert Street Bridge in neighboring St. Paul, Minnesota. By creating a comprehensive digital twin from over 57,000 images, the team reduced on-site inspection time by 20% while dramatically improving data quality. AI-assisted defect detection significantly cut labor costs, yielding over $90,000 in savings.

The digital approach enhanced safety by allowing engineers to proactively and remotely inspect conditions. It will also drive substantial savings during rehabilitation: up to $15 million for the Minnesota Department of Transportation (MnDOT) and a 10% reduction in construction materials. As Barritt Lovelace, vice president at Collins Engineers noted: “Using traditional inspection data collection methods would be very tedious and expensive, so our team had to find innovative ways to not only be more efficient but also to provide a higher quality deliverable for MnDOT.” Learn more from the project team.

Qk4’s engineers used Bentley software to build intelligent digital twins of more than 50 bridges that were damaged or destroyed in the flooding. Image courtesy of Qk4, Inc.

Qk4’s engineers used Bentley software to build intelligent digital twins of more than 50 bridges that were damaged or destroyed in the flooding. Image courtesy of Qk4, Inc.The survey and engineering firm Qk4 transformed Kentucky’s bridge infrastructure program by revolutionizing traditional survey methods. Facing the daunting task of inspecting 1,000 failing bridges in just six years, they embraced Bentley’s OpenRoads Designer Survey and 3D modeling technology, cutting survey time by 50% and reducing costs per bridge from $24,440 to $14,220. This digital transformation enabled them to survey 50 bridges a month—instead of 40 per year—while eliminating 20,000 land survey hours. The result: A remarkable $380 million in taxpayer savings and faster infrastructure improvements for rural communities. The work has already paid an important divided, when Kentucky experienced devastating floods in 2022. Digital twins and other technology allowed the state to recover and rebuild faster. As Royce Meredith from the Kentucky Transportation Cabinet aptly put it, “A picture is worth a thousand words, and a model is worth a book.” View the extended story and video.

A Fully Digital Approach to Bridge Design and Construction

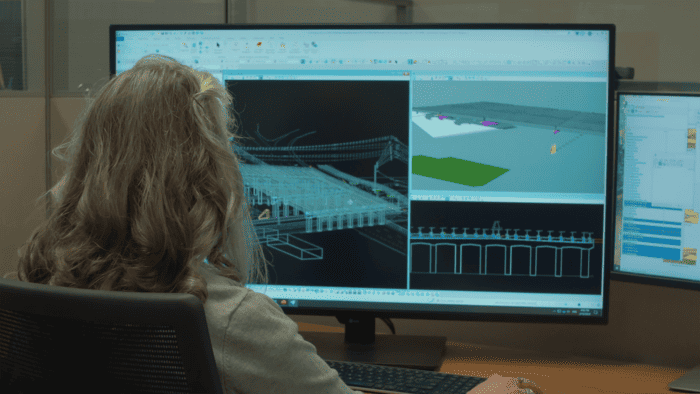

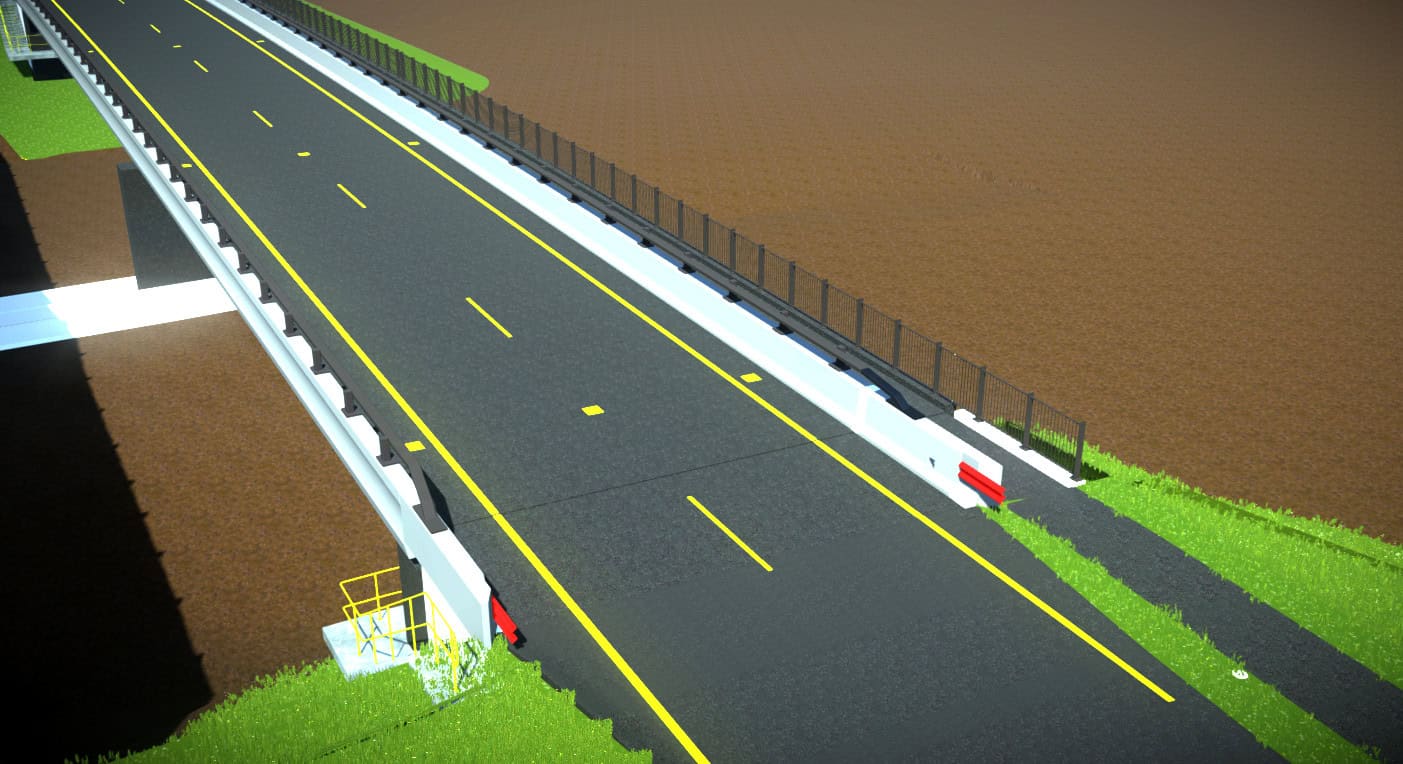

The Lathams Road bridge project in Australia was a major infrastructure upgrade to address increased traffic in the Carrum Downs suburb of Melbourne. Image courtesy of Hatch.

The Lathams Road bridge project in Australia was a major infrastructure upgrade to address increased traffic in the Carrum Downs suburb of Melbourne. Image courtesy of Hatch.At the Lathams Road Bridge Expansion in Australia, the engineering Hatch successfully executed a 100% digital bridge project. Using OpenBridge and OpenRoads software from Bentley, the team integrated bridge design, geotechnical analysis, construction planning, and maintenance forecasting into a seamless digital workflow. The result? Significant cost and time savings, reduced errors, and enhanced transparency across all project stakeholders.

Enhancing Decision-Making with Asset Analytics

I had a lot to share with the Philadelphia bridge inspectors, and I’m confident that their peers around the world can benefit from similar conversations. By utilizing digital twin solutions for bridge infrastructure and geotechnical data integration from the beginning, infrastructure owners and engineers can optimize costs, extend asset lifespans, and reduce unnecessary maintenance expenditures. To maximize efficiency in bridge inspections and predictive maintenance, we must move beyond traditional, manual data analysis. Bentley’s solutions empower infrastructure managers with AI-driven insights and predictive modeling, allowing them to assess bridge conditions at scale.

By leveraging historical performance data, real-time IoT sensor inputs, and machine learning algorithms, decision-makers can prioritize maintenance efforts and allocate budgets more effectively, ensuring that the most at-risk bridges receive attention before critical failures occur.

Oana Crisan is a senior product marketing manager at Bentley Systems. She’s specializing in software for designing and maintaining bridges and tunnels.