Repurposed from The B1M by Kathleen Moore

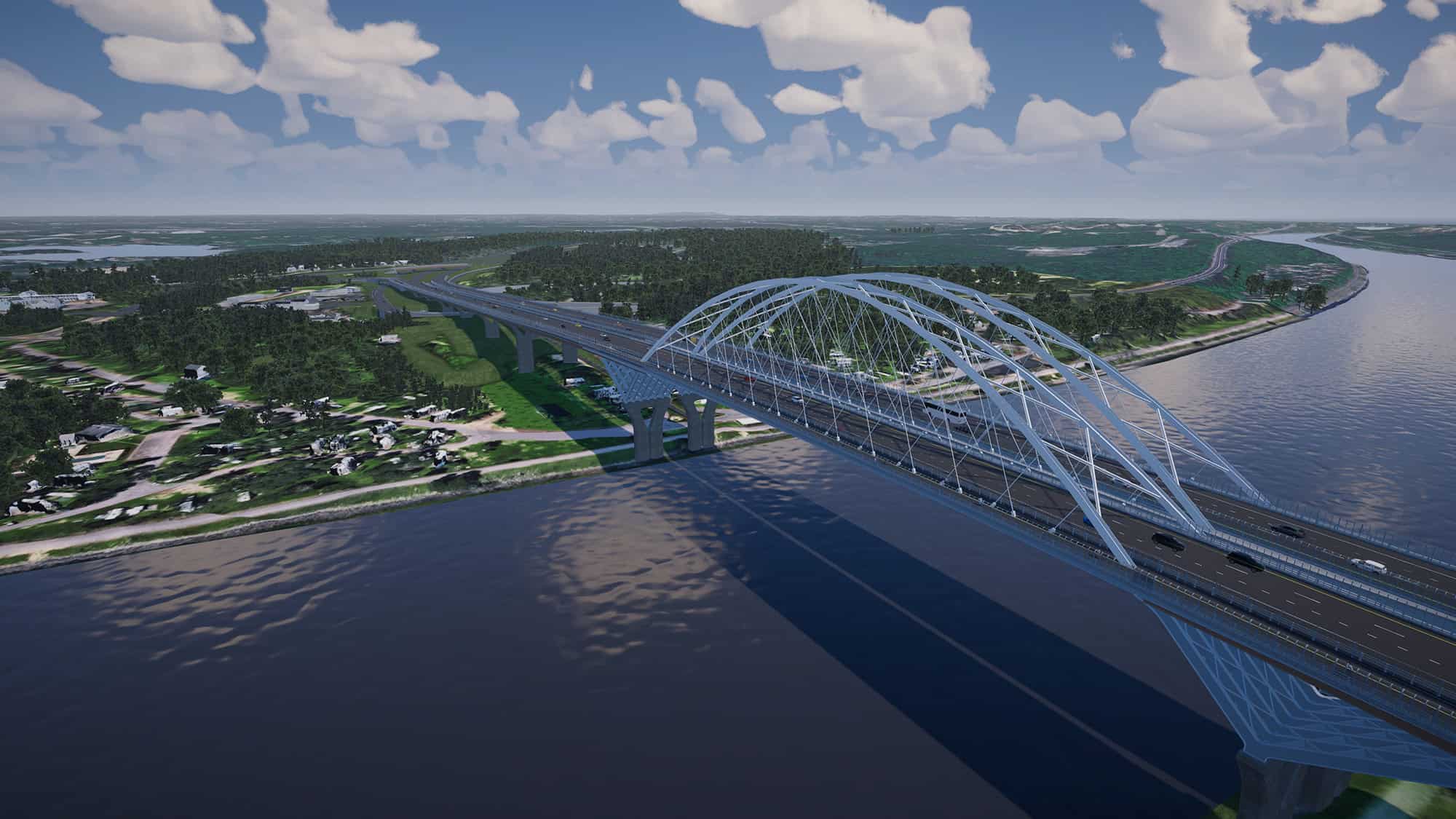

Melbourne is Australia’s largest container port – and it’s about to get a whole lot busier. The port handles more than one-third of the shipping containers coming in and out of Australia: Over 3.2 million of them, and that figure is expected to double by 2050.

There’s just one problem: How to manage that growth without adding to road congestion and air pollution in a city that’s already home to more than 5 million people.

“There’s only so much traffic that the road network can handle,” says Matthew Brooks, senior project manager at the Port of Melbourne. “And so we need to find other ways to get the containers in and out of the port environment.”

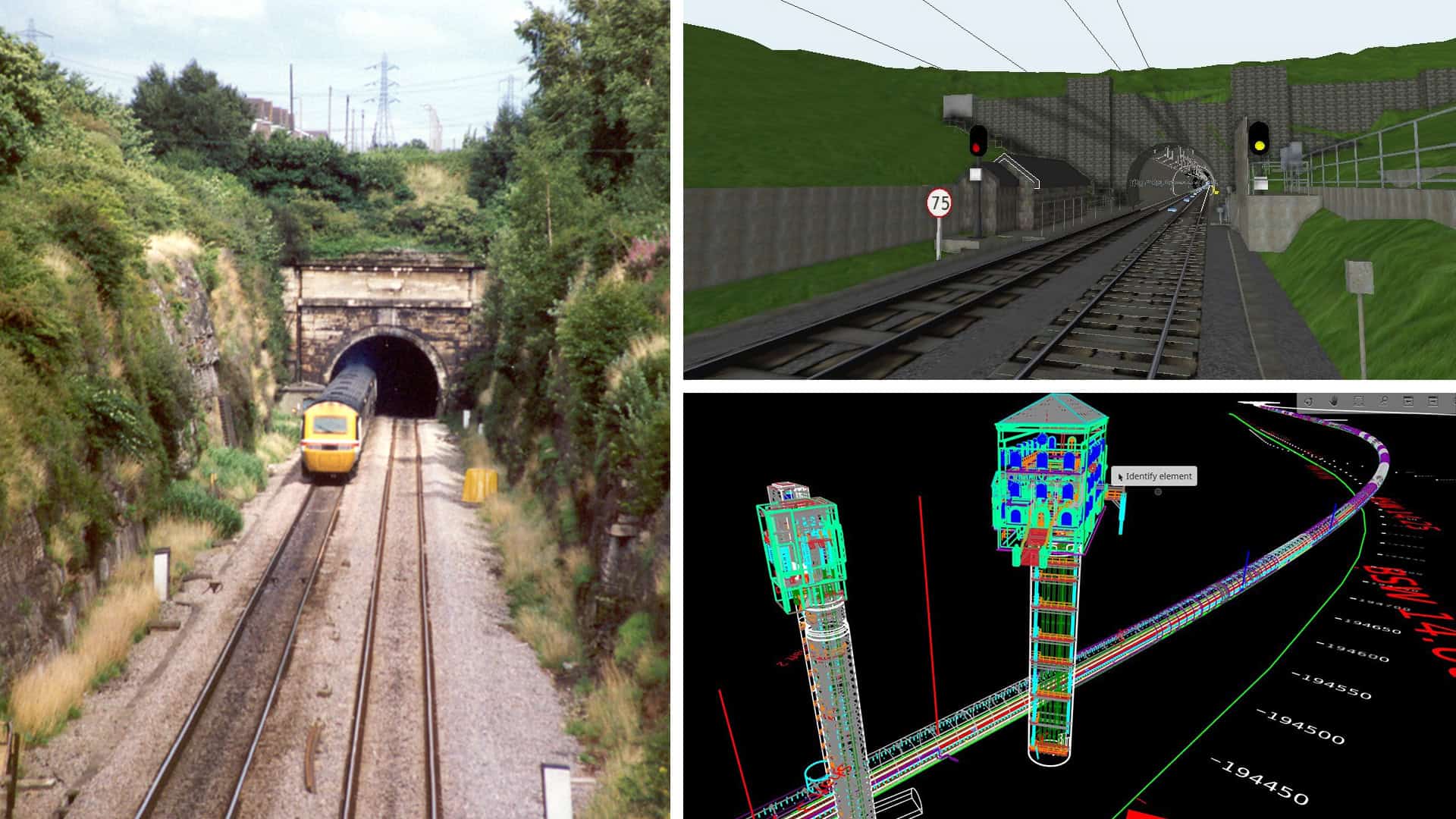

The answer is rails. A train can carry 30 times as many containers as the average truck. But the solution comes with challenges, like how to get the containers from the sea to the trains, without the fleets of trucks that currently shuttle between the two, and where to put all those containers on Melbourne’s already heaving docks.

The solution: Melbourne’s Port Rail Transformation Project. This complex set of projects, completed in 2024, called for a new rail terminal and improvements to existing rail and road networks, including that crucial direct link between ships and trains. Thousands of tonnes of pave material had to be smashed up and refined to make a base for the new terminal.

All this had to be done without disrupting the port’s daily activities, and within a tight timeframe. Design consultant WSP and contractor Seymour Whyte Construction had just 12 weeks to submit all the design documents and six weeks to produce the first results.

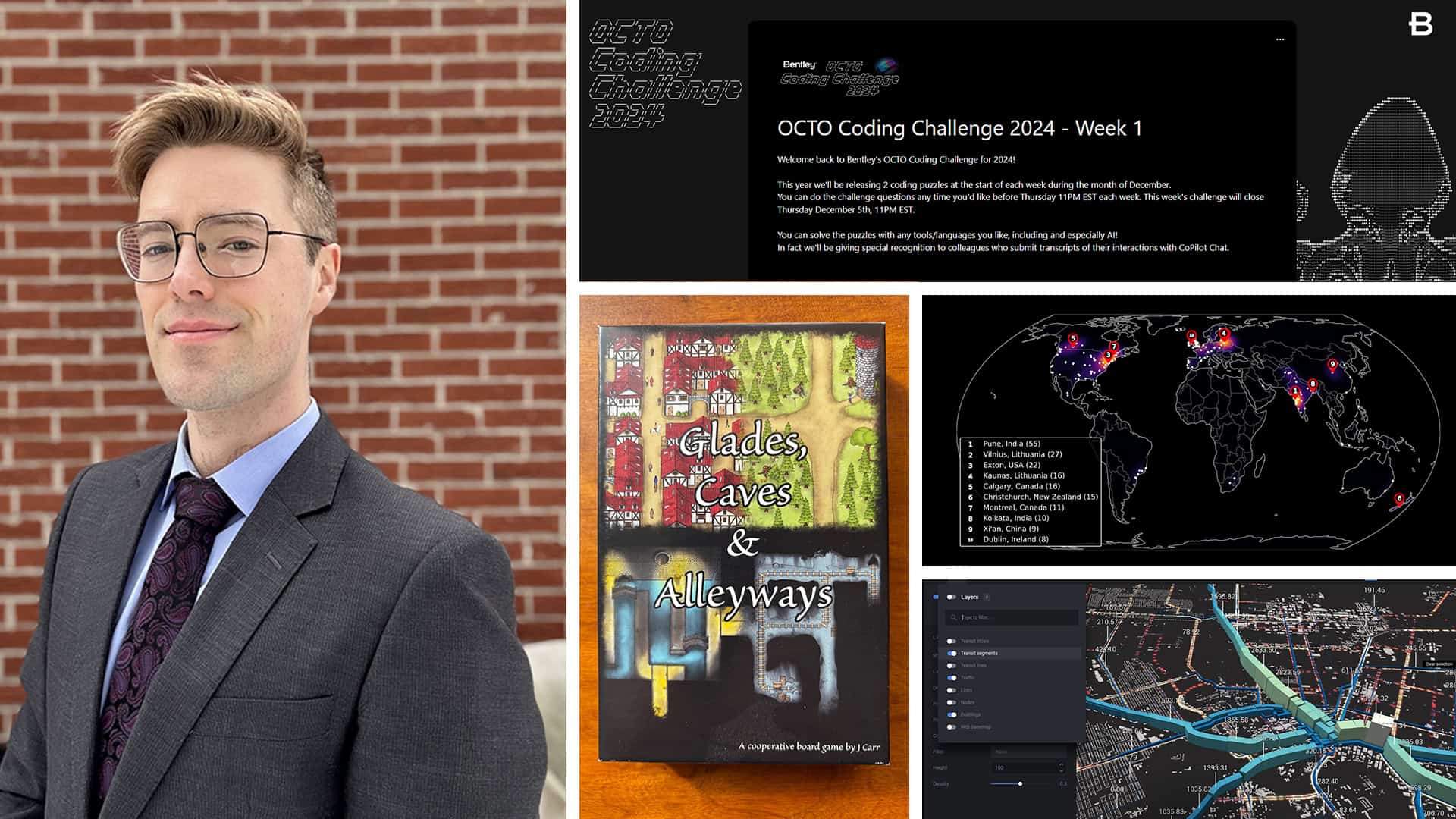

With more than 250 people working on the project, it was crucial that everyone could easily and closely collaborate.

Enter a solution based on iTwin and ProjectWise from Bentley Systems. This gave the team a one-stop-shop for all their data and digital models, allowing them to manage a huge amount of information. Teams were able to streamline their workflows, keep waste and rework to a minimum, and bring the project in on time.

“Given the tight time frame, we had to get everything right,” says Alex Yammas, WSP’s regional digital engineering lead. “This is where that single source of truth, connected environment really came into play.”

See this story on The B1M website.