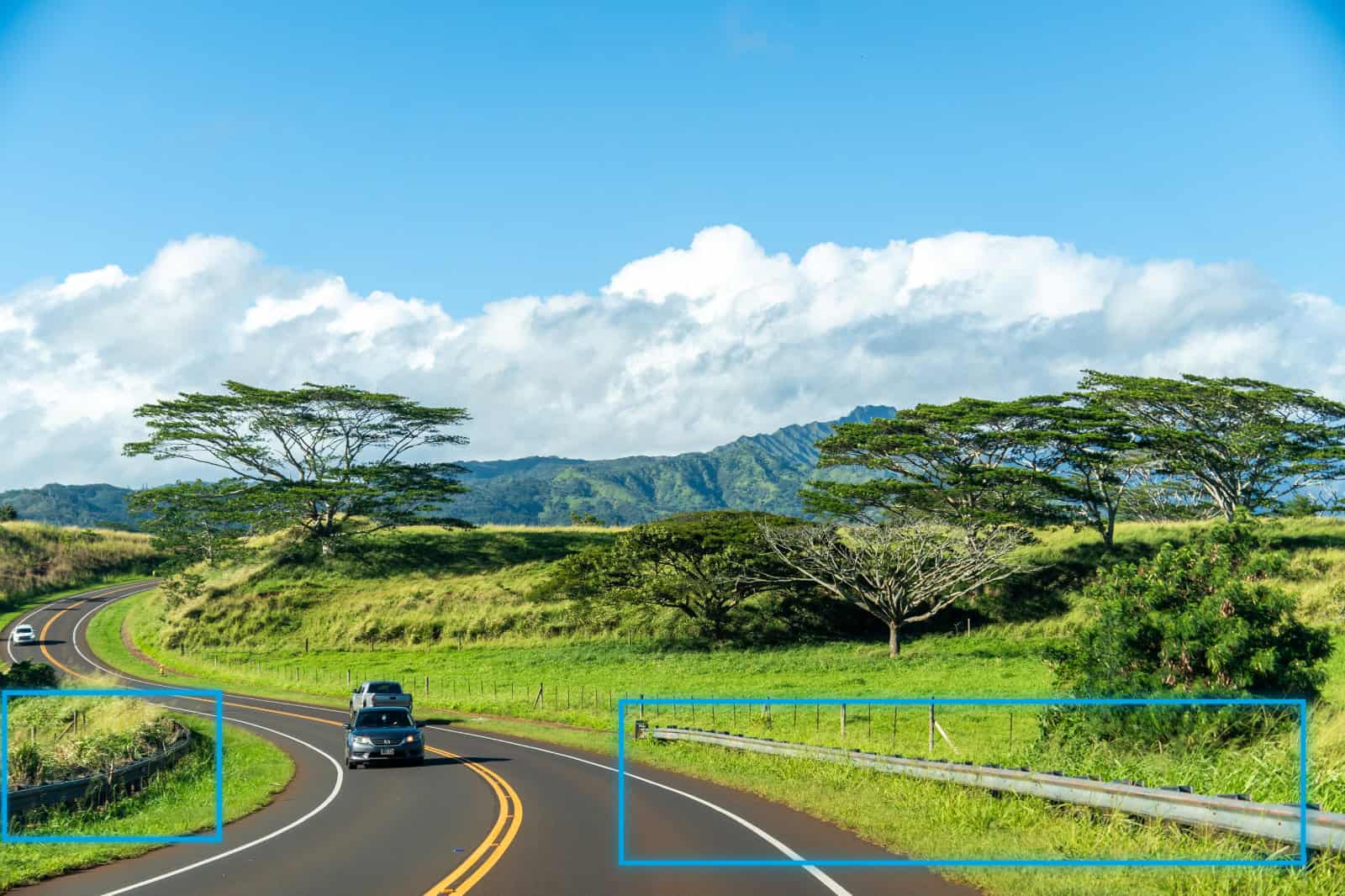

When the U.S. began building the Federal Highway System in the 1950s and 1960s , sustainability wasn’t a big topic of conversation. Few engineers and policymakers thought about the long-term environmental impact of shifting away from railroads and the growing reliance on oil as personal vehicles became the norm. The carbon footprint of such a massive transportation network? Hardly anyone gave it a second thought.

Today, the focus has shifted. “Carbon is now taking a more central role in how we design and deliver projects,” says Kelvin Saldanha, a highway engineer and associate director at WSP, one of the world’s leading civil engineering firms. He notes that even 15 years ago, engineers rarely considered a project’s carbon emissions.

Learn more about Carbon Analysis

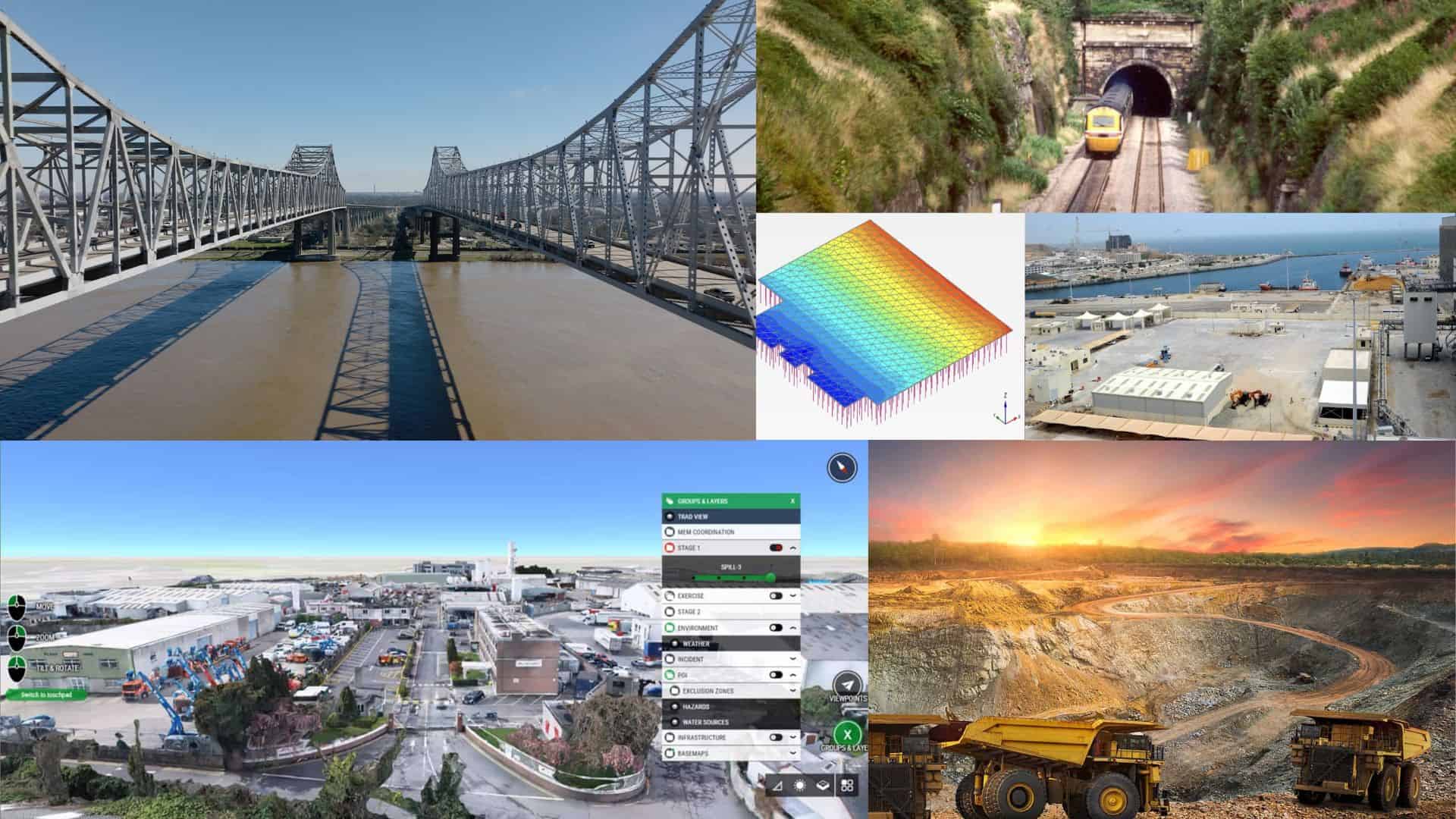

The infrastructure sector — which includes everything from roads and railways to wind farms and tunnels — now accounts for roughly 80% of global greenhouse gas emissions, Saldanha says. As the world grapples with the effects of climate change, the sector is rethinking how to reduce its carbon footprint while building the future.

Bringing carbon emissions into the equation is an important step. But firms like WSP have struggled with compiling carbon data for projects because of the wide range of methodologies used to calculate embodied carbon. The term refers to emissions coming from material sourcing and manufacturing, logistics and construction activities, including those associated with demolition and waste processing. “The process often required a lot of time-consuming work, translating every detail into a full carbon evaluation,” Saldanha says.

He’s now getting help from Bentley Systems, the infrastructure engineering software company, which just released Carbon Analysis capabilities that allows users to measure and reduce the embodied carbon footprints of their infrastructure designs and engineering projects. The capabilities are part of Bentley’s iTwin Experience

ITwin is Bentley’s platform for infrastructure digital twins. The capabilities make sustainability a more natural part of the infrastructure design process. Early adopters say that in the past, the embodied carbon calculation in large infrastructure could take six months. With the new capabilities, they can do it in minutes. The calculation covers the emissions from material sourcing and manufacturing, which represents 65% to 85% of total embodied carbon emissions.

Bentley’s iTwin is an “open” platform that allows users to centralize a wide range of data, including design, engineering and geospatial information. An infrastructure digital twin, which is a digital model of a real-word project, allows users to visualize in three dimensions the footprint of a project’s embodied carbon.

The new capabilities enable calculations of embodied carbon at any time during the design phase. Architects, engineers, material suppliers, sustainability experts and other stakeholders can use it to collaborate and make changes. “We’re connecting everything that’s disconnected,” says Rodrigo Fernandes, Bentley’s director for ES(D)G (Empowering Sustainability Development Goals). “Our vision is that the platform where digital twins operate should be open and flexible. This would allow users to easily extract data and switch systems without being locked into a single vendor.”

Being unable to move data due to file format and vendor lock-in has been a persistent obstacle to innovation for the infrastructure sector. Fernandes says that creating truly interoperable tools based on open platforms, like iTwin, is an important part of Bentley’s mission to create a sector-wide collaborative ecosystem. “We think that the platform where you have your digital twins should be vendor agnostic and should be open so that you can extract all the data there and move to something else if you want,” he says.

Industry impact

Saldanha, the WSP highway engineer, calls Carbon Analysis a “game changer.” He says the ability for companies to calculate carbon early in the design process will make it easier to work toward a project’s net zero emissions. The earlier you can calculate the carbon of a project, the better.

Studies show a potential 20% to 50% upfront embodied carbon savings by simply specifying and substituting material alternatives during the design and specification process. “This proposition from Bentley really represents a paradigm shift in the way we calculate carbon, but also in enabling a more consistent and rapid-fire approach to calculating carbon so that we can actually do it in time to have a positive impact on the outcomes of our projects,” Saldanha says.

Although people have been building aqueducts, bridges, sewers and other large infrastructure for centuries, even millennia, Saldanha notes that we’ve only recently begun to understand their environmental impact. Regulations, sustainability certifications and financial incentives are pushing for change, but the biggest force behind it is the urgent need to reduce greenhouse gas emissions. “If we don’t challenge the status quo, the ambitious net-zero carbon goals set by many governments will be tough to meet,” he says. The only way forward, he stresses, is to embrace new ways of doing things. “This,” he says, referring to Bentley’s Carbon Analysis , “is doing things differently.”

Bentley’s Carbon Analysis is now available.