- Increase management efficiency, benefiting reduced operation (e.g., energy, consumables, etc.) and capital costs

- Improve metering and billing – fewer leaks and improved performance can positively impact apparent leak results

- Decrease structural damage – leaks can cause voids underground and consequently damage roads and buildings

- Reduce ecological stress

- Reduce sewer systems overload – lost water normally infiltrates the sewer system and consequently increases the flow to the wastewater treatment plants

- Increase customer satisfaction by improving the quality of the service and guaranteeing sufficient water quantity, quality, and pressure – leaks and ruptures can result in a pressure drop

Strategy for addressing water loss

Overall, regulatory authorities are increasingly forcing water utilities to implement more effective management and control measures to reduce water losses, and performance indicators must be pursued and accomplished. As established by Water Europe, a recognized voice and promoter of water-related innovation and research and technology development (RTD) in Europe, one of the water sector’s key impact parameters focuses on “reducing water ‘loss’ in the overall human-built water system, from the current estimated average of 20% across Europe to lower levels, taking into account regional differences of sustainable water availability (which could make another estimated 50 km3 /yr of water available for multiple uses)” 3. To move toward this goal, besides the implementation of an integrated water leakage control strategy, there is a strong need to develop a systematic approach that identifies likely leakage hotspots, so that detection crews can quickly identify leaky mains, resulting in faster repairs. This is where OpenFlows Water – Darwin Calibrator for leakage can be valuable.Performing leakage detection using the Darwin Calibrator

There are several techniques currently used for detecting where leakage is occurring in a water distribution system, including random or regular sounding surveys, step-testing of sub-systems, and acoustic loggers as a survey tool. However, applying the current leakage detection apparatuses and procedures to all water pipelines throughout a system is time-consuming and costly for a leak detection crew. Additionally, leaks are also becoming harder to find. One reason for this is pressure management. Not only is leakage being routinely suppressed by planned pressure reduction but also the same reduction leads to less acoustic disturbance from those leaks. Additionally, sounding for leaks has become more difficult as ferrous mains are replaced with less acoustically responsive plastic pipes1. One way to achieve cost-effective leakage detection is to leverage the well-established computer-based hydraulic modeling technology. The water industry has accepted hydraulic modeling as a routine computer simulation tool to analyze the hydraulic characteristics of the system elements (pipes, pumps, valves, and storage facilities). When properly implemented, models become a fundamental part of the decision-making process for planning, designing, and operating a water distribution system.How to identify leakage hotspots?

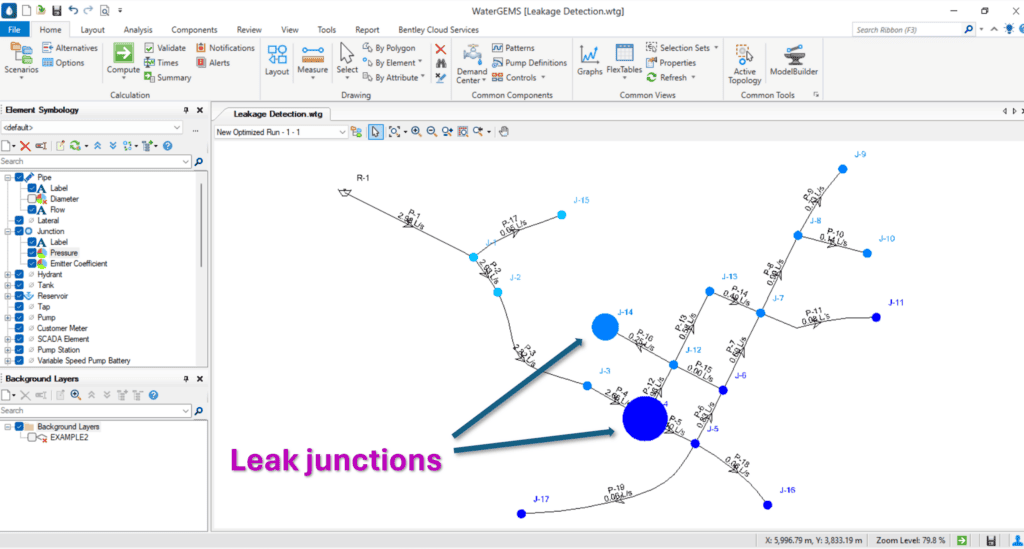

OpenFlows Water – Darwin Calibrator employs a powerful competent genetic algorithm search method based on the principles of natural evolution and biological reproduction, to identify leakage hotspots. This search algorithm is well suited to the optimization of problems of a non-convex and multiple local-optimal solution nature. A leak causes an increase in pipe flows which results in additional head loss and a subsequent drop in pressure. By comparing measured results from sensors at specific locations with the calibrated hydraulic model results, the Darwin Calibrator is able to automatically geolocate the potential leak(s) (at the node level), thus enabling more efficient leakage reduction programs4.

How does leakage detection work?

The Darwin Calibrator works by adjusting the emitter coefficient (a pressure dependent demand) at the nodes in order to get the model to match the field data. It can use the genetic algorithm to move leaks around the system until the pressures in Darwin match those from field measurements. Those leak nodes indicate the approximate location of the leaks(s), and leakage detection crews can then pinpoint the exact place.

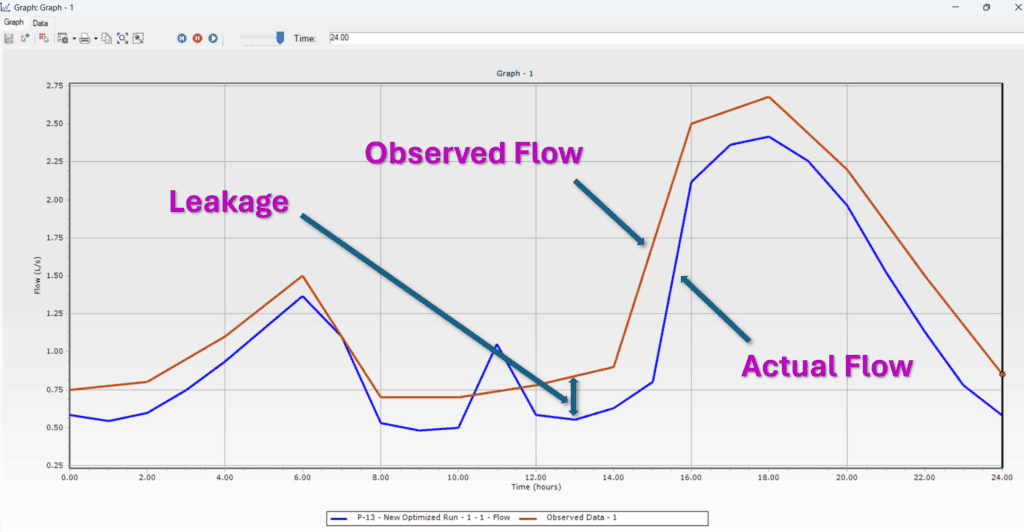

The graph shows the actual flow for a pipe at various time steps and the observed flow on the field. With the help of this graph, you can visualize the leakage at the determined locations, by using the actual flow in the model vs. observed flow on the field. The difference between the actual flow and the observed flow is the leaked flow into the system.

OpenFlows Water – Darwin Calibrator can support water utilities on leveraging a cost-effective leakage detection strategy and thus improve water supply system’s performance.

You can take a look at the use cases below to check how utilities are already benefiting from this tool:

- Companhia Águas de Joinville Keeps Clean Water Flowing for 600,000 Residents in South Brazil

- AEGEA Implements a Digital Twin at Manaus’ São Jorge District to Improve Water Quality and Asset Management Decisions

There are several other resources available online that can provide you with further information on how to use Darwin Calibrator for leakage. More detailed information can be found here:

Unlocking Advanced Modeling Analysis To Improve Water Distribution Systems With OpenFlows

Available On-Demand

References:

[1] Wu, Z. Y. (2008). Innovative optimization model for water distribution leakage detection. Watertown, USA: Bentley Systems Inc. https://bentleysystems.service-now.com/community?id=community_document&sys_id=85258ce697b18610afb952800153af6d

[2] IWA (2022). Water Loss Specialist Group (WLSG) Position Statement. https://iwa-network.org/wp-content/uploads/2022/03/IWA-Water-Loss-SG-position-statement-March-2022-1.pdf

[3] Water Europe (2023). The value of Water Towards a Water-smart Society. https://watereurope.eu/wp-content/uploads/2023/11/WE-Water-Vision-2023_online.pdf

[4] Bentley Communities (2024, April 12). Tips for Water Loss Management and Leak Detection. https://bentleysystems.service-now.com/community?id=kb_article_view&sysparm_article=KB0058696