M/Y Aurelia

Fano, Pesaro, and Urbino, Italy

A Custom Home – At Sea

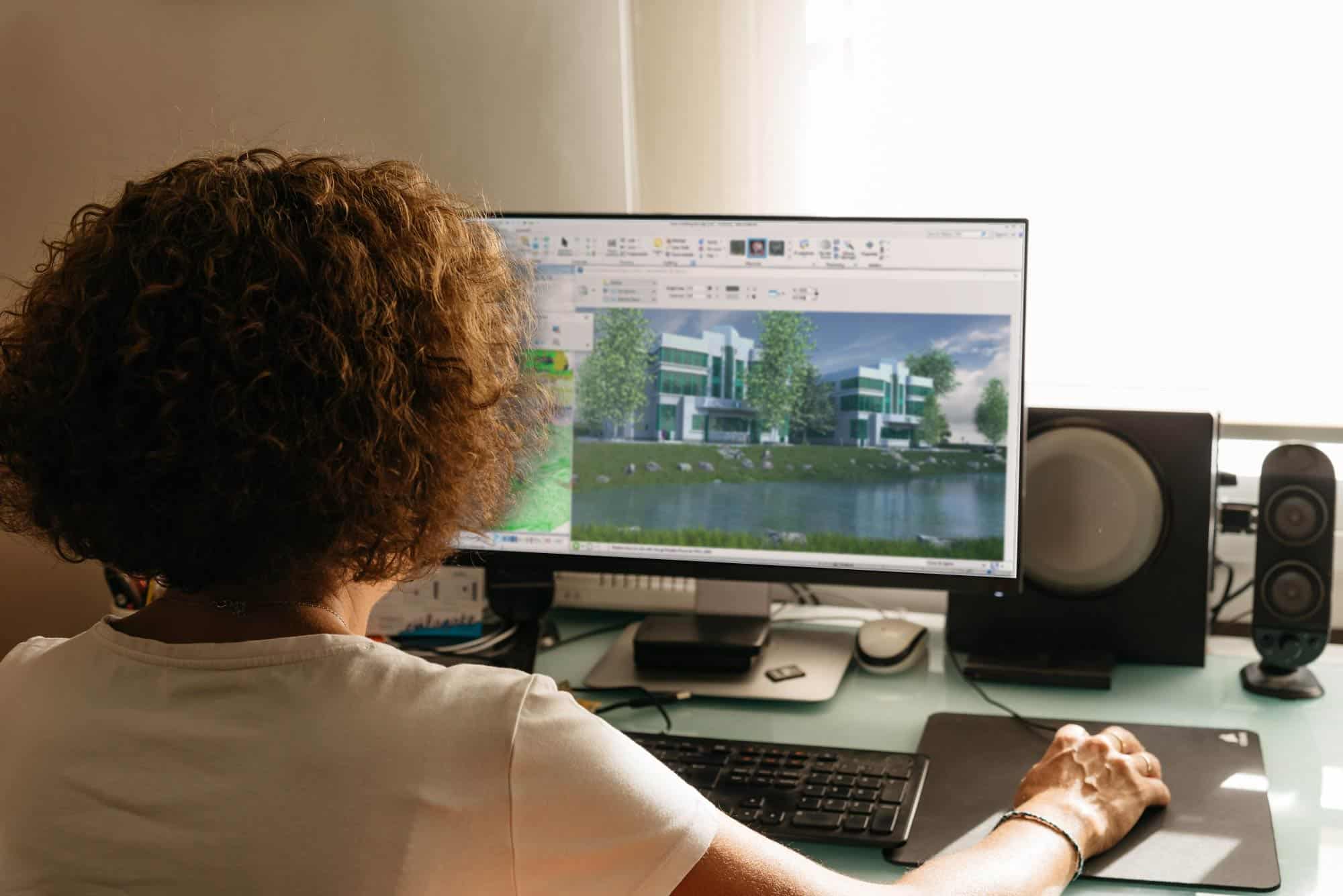

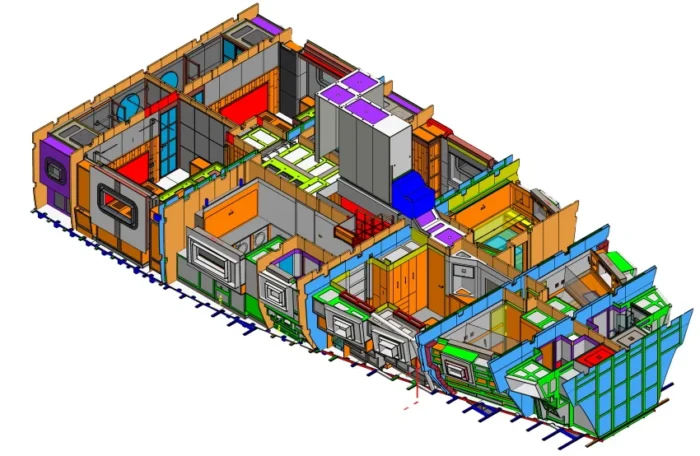

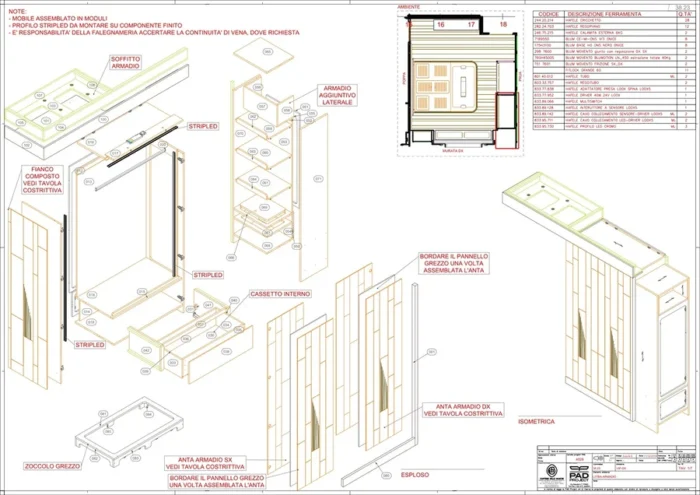

M/Y Aurelia 29 is a 39.23-meter-long yacht with a waterline length of 38.23 meters, featuring a steel and aluminum displacement hull and three decks. One of the first of the innovative Flexplorer line introduced by Cantiere delle Marche. Pad Project was hired to perform 3D design engineering of the furnishings but faced an unconventional industrial architectural style where modernity meets vintage, uncommon in the nautical field. The boat’s interior required them to design approximately 46,000 components and manage over more than 300 square meters of furniture surface to be engineered. To accommodate the unique architectural guidelines, numerous modifications, and a large number of files, they needed flexible 3D modeling technology. Enter MicroStation.

The 3D Solution

They selected MicroStation to integrate 3D point clouds and create a cross-referenced information flow with third-party software, managing thousands of files without slowing design. MicroStation enabled the team to work simultaneously in a single environment in real time and modify the architectural elements timely and cost effectively. The digital solution decreased production times and reduced modifications by the on-board fitters by 50%.

Rino Zaccaro , CEO of renowned Italian design and engineering company, Pad Project, explained why the entire 3D project was developed using MicroStation. “The Bentley software offers the flexibility to make the continuous modifications required by the architect and the ability to directly integrate the point cloud (the result of modern laser survey systems) to fully visualize the hull together with its technical systems. This made it possible to carry out constant verification of structural interference and ensure compliance with architectural guidelines.” Subsequently, the Progenio app made it possible to encode and assign all metadata – such as unfinished support, finishes, processing cycle, weight – to every single component of the furniture in order to ensure traceability and repeatability of each individual piece.

The Impact of Going Digital

Reference-related MicroStation technology allowed Pad Project to create an information flow based heavily on cross-references, thereby optimizing the management and control of thousands of files without slowing down the design.

The complex boat system was divided into decks, decks into cabins, cabins into furniture and the furniture broken down into individual components through Progenio. Creating cross-references allowed the complexity of the entire project to be broken down, as doing so allowed the team to work simultaneously within a single environment by sharing changes and improvements in real time.

The design system adopted, enabled the time it takes to produce and install the interior to be reduced and all changes to be managed without compromising contractual delivery times.

The Advantages of a Precise Design

The benefits of a precise and flexible design were appreciated across the team:

- Joiners decreased production times thanks to MicroStation and Progenio giving them the ability to go to the cutting machine simply by reviewing the project for conversion to CAD/CAM.

- On-board fitters reduced modifications and remaking of parts on board by 50%, consequently saving time and increasing profit margins.

- Having virtualized the entire hull, they were also able to receive continuous and realistic support and feedback on installation, which allowed them to expedite the work.

- The customer was able to manage the furniture contract by dividing it over several joiners and obtaining a uniform product thanks to a precise and detailed project.

- The final result was particularly appreciated by the owner, as the furniture successfully represented his unique style, along with comfort, in a welcoming environment in which to enjoy the yacht with family and guests.

Software

MicroStation is the computer-aided design (CAD) software that users worldwide trust for creating precise 2D and 3D drawings for infrastructure projects. Engineers, architects, and construction professionals openly collaborate to deliver inspiring projects, utilizing the industry leading DGN file format. MicroStation can help you deliver your designs on time and on budget, even as project complexities and scale increase. Progenio is the only software design and developed for bespoke, nautical, and contract furniture. Progenio is a product of Planstudio, a Bentley Platinum Channel Partner.

The advantages were appreciated across the team, including on-board fitters who reduced modifications and remaking of parts on board by 50%, saving time and increasing profit margins.

Rino Zaccaro CEO, Pad Project Fano, Italy

Facts

- The entire 3D project was developed using MicroStation.

- The complexity of the constituent elements necessitated the design of approximately 46,000 components, over more than 300m2 of surface to be engineered.

- Reference-related MicroStation technology enabled the creation of an information flow based heavily on cross-references, thereby optimizing the management and control of thousands of files without slowing down the design.

- The solution enabled Pad Project to reduce the time it takes to design and draw up production data sheets, providing the customer with a permanent overview of the project and the flexibility to modify architectural elements without impacting the time and costs of review.

Image: Courtesy of Cantiere delle Marche