It was a rainy Friday afternoon, back when I was executive director of the Wyoming Valley Sanitary Authority, a regional wastewater system. We had a long force main along the river that intercepted flow from several municipal pump stations along its route.

Did someone call about sewage in the street?

We had been getting complaints from one town that they had sewage in the street, at a particular location. We’d send out a crew to track down any leaks, but they couldn’t find any evidence. We asked the water company if they could find leaks in their system, but they couldn’t find any either. This was going to be one of those problems that would reveal itself eventually.

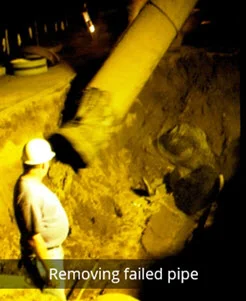

Eventually arrived that afternoon. We received a call from that neighborhood, and my Operations Director and I decided to drive out there and see for ourselves. Yes, there was water in the street, and it was most likely sewage. It was not going to be one of those problems that would heal itself. To wait until Monday would not be a good option.

Where do you quickly find a new 30-inch concrete pipe?

The force main in that area was a 30-inch prestressed concrete cylinder pipe and it was leaking. Did you ever try to buy a 30-inch concrete pipe with closure pieces late on a Friday afternoon? It’s not one of those items you can pick up at Home Depot or Lowes. We hustled and found some of the pipe we needed in storage in Baltimore. We had them load up a truck and ship it overnight. We hired a contractor who could handle a large pipe like this, and they worked around the clock until they repaired it.

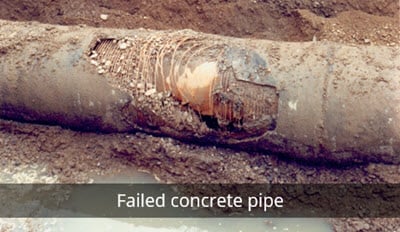

Why did the pipe fail, and why did it happen there?

But why did this happen and why did it happen there?

The area was fairly flat, but not completely. If you looked at it carefully, you’d notice that it was a local high point. So what? If you have a high point, gases from the wastewater will collect there. If the gases are things like oxygen and nitrogen, not a problem. But that’s not what you have in wastewater.

You won’t find hydrogen sulfide in sewage leaving a customer’s house. It forms in the anaerobic conditions in a sewer. But hydrogen sulfide doesn’t stop there. In the right mixture with moisture and microbes, it forms sulfuric acid. If you let concrete sit in sulfuric acid long enough, it will destroy the concrete. And what were these pipes made of – concrete. The crown of the pipe had been eaten away. And the pipe was only about 30 years old.

Why wasn’t this leaking all the time?

It was a high point, and during dry weather flow, the hydraulic grade line was either in the pipe such that the pipe was not flowing full or just above the pipes such that the sewage didn’t reach the surface. However, when heavy rain hit, the hydraulic grade line rose above the ground and the neighbors were greeted by fresh sewage.

Most high points on force main are equipped with air release valves which release the hydrogen sulfide and other gases from the pipe. This high point was so mild that it seems no one thought it would be a problem (until that Friday). With mild slopes, one would expect the corrosive gases to be dragged downstream with the flow. Apparently, the velocity in this force main wasn’t sufficient to do that.

Why don’t situations like this happen more often?

But we didn’t merely decide to replace a few pieces of pipe. We didn’t want this to happen again. So, we decided to slip line a considerable length of the force main with high-density polyurethane pipe (HDPE). This was an interesting project because we couldn’t simply turn off the upstream pump stations. We needed to provide bypass pumping during the project duration. But we probably didn’t need a full 30-inch bypass pipe. We ran our hydraulic model and found a smaller pipe that would be adequate during the project duration. This led to an interesting installation where we were sliplining the 30-inch pipe while bypassing upstream flow for a few days.

How do you know you are going to have this kind of problem?

You can run the model of the system and focus on the high points. Some can intermittently flow full and partially full. These will definitely need an air valve. But even the high point that is always flowing full will need air valves. Using a piping material that isn’t adversely affected by hydrogen sulfide will also help.

When will gases accumulate at a high point as opposed to being dragged downstream in the flow?

That depends, primarily, on the velocity of the flow and the steepness of the downward sloping pipe after the high point.

A few years later, when I was teaching environmental engineering at Wilkes University, we conducted a project to determine what conditions resulted in gas pockets forming at high points. We did a theoretical analysis of forces acting on gas pockets and laboratory test runs to verify those calculations. Those results were published in the paper:

Walski, T., Barnhart, T., Driscoll, J., and Yencha ,R., 1994, “Hydraulics of corrosive gas pockets in force mains,” Water Environment Research, Vol. 66, No. 6, p. 772-778.

The work enabled us to predict where future failures would occur, and they subsequently have occurred.

Want to learn more from our resident water and wastewater expert? Join the Dr. Tom Walski Newsletter today!