Geotechnical consultant CMW Geosciences’ complete transition to OpenGround by January 2020 was incredible timing given the pandemic that ensued. In 2022, they now hold 68,000 boreholes, constituting some 671,000 metres of drill logs centrally, improving collaboration for better, data-informed decisions by all project contributors.

The Project

CMW Geosciences is a privately owned consultancy providing specialised geotechnical services to the mining, construction, and civil engineering industries. First established in 2012, CMW has maintained continued year-on-year growth and services a global client base from its offices across Australia and New Zealand.

In 2018, CMW made the decision to move to 100% cloud-based geotechnical management after considering risks to their on-premises operations, such as server failures, office fires, or even a pandemic. They were an early adopter of OpenGround, the geotechnical information management platform that enables easy access, collection, reporting, management, visualisation, and analysis of data.

CMW’s Director, Senior Principal Geotechnical Engineer, Craig Butterworth, comments, “By February 2020 everything was cloud based, which was incredible timing given what unfolded with the pandemic soon after. Now in 2022, we have 68,000 boreholes, constituting some 671,000 metres of drill logs all held centrally in OpenGround. We are more connected, have better access, and can also collaborate more readily with staff, clients, and suppliers.”

Situation

CMW, having grown quickly and organically, had been unable to easily replicate services across multiple offices. This had resulted in their having two geotechnical databases held on servers in Perth, Australia and Auckland, New Zealand. The Perth server in particular had internet connection issues which caused intermittent data access problems for the other Australian offices, which aside from being frustrating and a security risk had a financial cost.

Collecting data from remote regions, generally by hand at drill rigs, meant that data capture at source was also inefficient. This complex data was handwritten and then retyped back at the office into desktop applications. Aside from being repetitive and inefficient, this was wasting skilled worker’s valuable time in an industry beset with skill shortages.

“Many activities were being performed manually, which often led to repetition, delay, and vulnerability to error,” explains Craig Butterworth. “An early goal was to ensure that no one entered BH01 more than once.”

Response

Recognising the risks associated with these inefficiencies and being advised by trusted supplier, Keynetix, (acquired by Bentley in 2019), CMW decided to fully commit to the move to the cloud. They chose OpenGround, which enables greater interoperability and integration with other software thanks to its platform features and API.

Roger Chandler, OpenGround’s Director of Geotechnical Information Management, says, “OpenGround creates an easy way to store current data and access historic data to maximise the information available. It also allows the data to be easily transferred through different stages of the project and into other software packages.”

Deciding what data to hold

A key decision was determining how much data to take to the cloud, whilst still being open to new opportunities that future innovations could bring. This was an ongoing discussion between Roger and Craig.

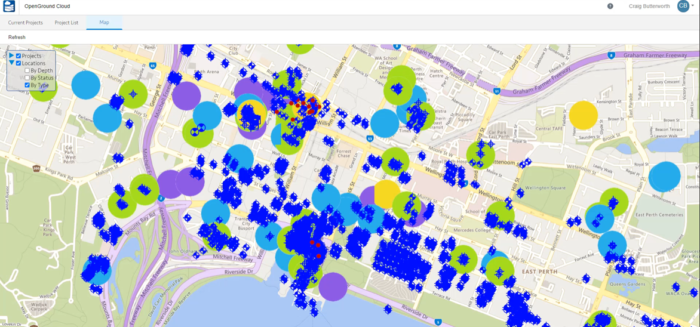

Craig Butterworth explains, “Did we want to enter old logs, for instance? The effort involved could be astronomical, so it was important to weigh against overall value. But then we also had to consider future OpenGround capability and the possibility of linking data from neighbouring projects. What if you could literally draw a line through the whole Central Business District and then have all the logs come up?”

Their decision to store as much information as possible now means, for example, that they can start to study geotechnical data across projects to greater understand the variability of various stratigraphical units within a specific region. This enables CMW to synthesise much more knowledge and improve decision making.

Moving to the cloud

To combine the Australian and New Zealand databases, CMW uploaded database files to the OpenGround team. As CMW were adding data to their local server every working day, they worked with the Bentley team to ensure minimal downtime.

Craig Butterworth comments, “It was amazingly seamless. Friday we were working on our local server and on the Monday we all logged onto the cloud. We had a few latency issues initially as the server was in the U.S., but now we have access to the Australia-based Microsoft Azure and no latency issues.”

With all data in the cloud, some of the common data entry problems could be tackled.

Capturing data at source

There was a need for a field system that could readily secure the data in a way that ensured staff buy in. The data capture involved in producing a typical borehole is surprising significant, with some 800 individual cells, which includes some 56 cells of narrative on detailed soil descriptions that were considered too complex for a drop-down menu selection on a tablet. However, the factual data could be entered more easily at source.

Starting with the simpler factual data allowed CMW to offer loggers a step-change and, as confidence grew, they could tackle the more complicated data. This approach also allowed everyone to quickly appreciate the time savings. CMW was also able to offer the loggers onsite help with soil descriptions and in understanding the data. The new approach was demonstrating benefits early on – just collecting data more effectively in the field and not having to retype back at base was saving an hour or two per borehole.

“Not only were work practices improved and we were able to see data quickly and analyse it, but everything was also being loaded to a secure server,” explains Craig Butterworth. “Valuable information wasn’t first being handwritten on a piece of paper that was susceptible to something as basic as getting wet prior to being typed into a desktop.”

Staff and user buy-in continues to be an important consideration, with champions in every office to train new staff in OpenGround and keep everyone up to date with advances. To help increase confidence and capability, CMW encourage OpenGround use for even small jobs, getting people into the mindset of best practice and understanding why it is important.

“Using OpenGround for every job means that when they do the large 50 borehole job, they’ll know exactly what to do and they realise the time savings,” comments Craig Butterworth. “They can use the time to do more interesting things than typing data into boxes, freeing time for better analysis.”

Sharing data for collaboration

Team members and clients were given access to data using customisable role-based permissions, accessed via a simple web browser using everyday software. Clients could quickly review their logs and visualisation was much enhanced, with the ability to zoom in and strip out individual boreholes, improving understanding and communication.

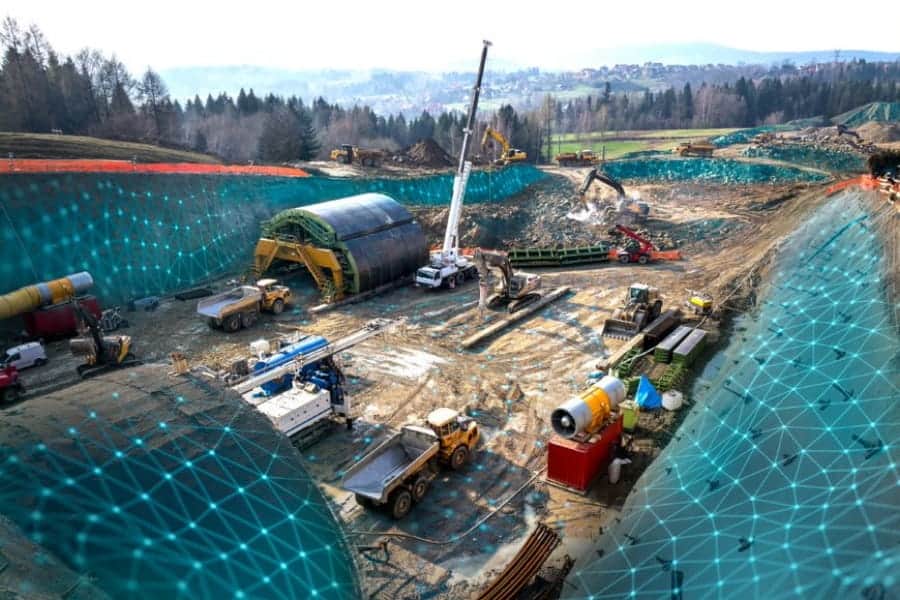

A recent road project with the Greater Connect Alliance in Perth is a good example of how collaboration vastly improved. Using GIS data in the cloud, CMW was able to separate out Hydro and Geotech data and share it with the alliance stakeholders. Different stakeholders were able to import their data to the cloud and everyone could see live what they were uploading.

Craig Butterworth comments, “Contractors were able to go in and look at the location and plan their traffic management. With the real-time login, clients could see what was being done and their designer could quickly get started. We were able to start creating geological models and schedule testing.”

OpenGround Data Collector

CMW are now using the OpenGround Data Collector to log data live to the cloud. With an earlier tablet system, CMW logged data at source and then synced to the cloud once back at base. With the Data Collector information is available straightaway for interrogation and analysis, saving more time and potentially costly returns to the field.

Craig Butterworth comments, “We might notice that one team’s descriptions aren’t the same as another’s. We can pick up on that and do something about it to ensure consistency in approach across the job”. And then there are situations where you might want to drill deeper. With live logging the field staff have access to more senior personnel in the office who can view logs and collaborate more effectively to make critical decisions without delay or without terminating a hole too early.”

Outcome

The overarching benefit of the move to OpenGround has been reduced risk. This was quickly realised when the pandemic struck and working and collaborating remotely became the norm. Everyone could log into OpenGround and share their latest insights. Teams were able to work much more effectively from this single source of truth.

Improved geotechnical data reliability

OpenGround gave teams access to federated data across connected applications using many devices, improving reliability and project efficiency. From a risk management perspective, CMW can now identify gaps in the data much more easily, highlight risk items, and assist in the planning of targeted ground investigations.

Data is much more readily available from the source and can be quickly transferred to OpenGround, whether that’s loggers collecting data at drill rigs, cone penetration testing suppliers gathering data, or labs supplying test results. This streamlined approach means that geoscientists can spend more time looking at the data rather than organising it.

These efficiencies save time and accelerate project efficiency. CMW are also more competitive, passing on savings in the tender process as repetitive tasks are eradicated.

Improved operational efficiency

Since moving to the cloud, CMW now literally only need a phone and a laptop to start a new office. This means reduced capital investment and lowered risk with more targeted IT support to improve processes.

From a quality assurance and compliance perspective, CMW are avoiding duplication and the risk of error. Everyone works from the same templates and CMW can consistently roll out any changes needed to everyone. This also means data can be easily audited.

Open digital workflows

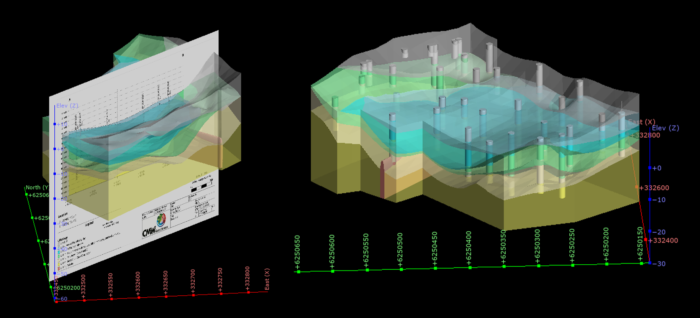

Teams collaborate whether they are collecting data in the field, reporting, managing, or integrating data with their design or analysis software. The platform has several connected applications to provide team members with the tools they need in a modern, intuitive environment. OpenGround is part of Seequent’s Geotechnical portfolio that includes GeoStudio and PLAXIS. As Seequent is now part of the Bentley family, there are multiple opportunities for integration with leading solutions to facilitate open digital workflows across the entire lifecycle of a project.

Craig Butterworth comments, “We’re already linking with Leapfrog Works, but this is only going to improve as there is more integration between Seequent and Bentley solutions. We can now update models as data in the cloud is updated.”

OpenGround is also able to handle open data formats for transferring geotechnical and geoenvironmental data between parties. CMW are already seeing the benefits of this with increasing demand for the Association of Geotechnical and Geoenvironmental Specialists (AGS) data format, the industry-standard exchange format for geotechnical data in the UK and Australia.

“AGS is hugely important in enabling supplier and clients to easily share data across different software,” explains Craig Butterworth.

Craig Butterworth concludes, “The OpenGround team were our partners, working closely to ensure a smooth transition. We’re committed to technical excellence and application throughout the full project life cycle, and OpenGround is helping us realise our goals.”