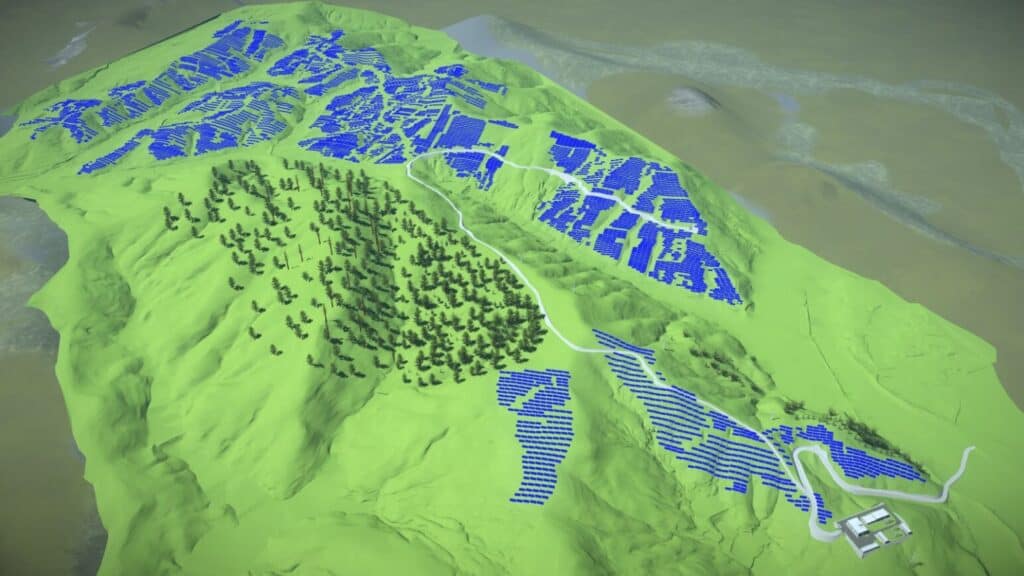

POWERCHINA Hubei Electric Engineering Co., Ltd. / Photovoltaic Power Project

guangshui, china

Solution

When POWERCHINA Hubei Electric Engineering was hired as the engineering, procurement, and construction contractor to deliver an 80-megawatt ground-based photovoltaic power station, they faced several challenges, including saving land and raising the generating capacity target of the photovoltaic station; designing the optimal layout plan for hilly areas according to the policy of going green and environmental protection; ensuring project quality, controlling project costs; and meeting a short 10-month schedule with a requirement to realize lifecycle digital twin application. Topographically, the site is dominated by low hills and slopes, with barren hills, pine woods, and fish ponds. As a result, choosing a proper location for the photovoltaic array, booster station, access road, and the transmission line was critical to produce an optimal design. They originally used third-party design software but quickly realized that it was inefficient and that they needed integrated dynamic modeling technology.

Software

POWERCHINA Hubei selected OpenBuildings Designer and OpenRoads for 3D modeling, as well as ProjectWise for collaborative design management. With Bentley applications, they developed photovoltaic design software for mountainous photovoltaic power projects. Using the robust solution, they were able to reduce design errors and manual verification, which produced a more efficient design. The solution optimized the design scheme, reducing land occupation and avoiding 40 potential rework scenarios to save more than CNY 800,000. Integrating SYNCHRO 4D accelerated construction by approximately 30 days. They used the Bentley iTwin platform to automatically generate digital twin models, avoiding approximately CNY 1 million in costs had the digital twins been developed at the operation stage.