It’s difficult to pick up an engineering magazine or journal without seeing an article about how artificial intelligence (AI) is going to solve all of our problems. While these tools are indeed powerful and useful, are they really the panacea that they are sold as?

For this blog, let’s contrast AI models with physics-based models. Physics-based models are those based on scientific principles like F = ma or mass in = mass out, or empirical relationships such as Manning’s equation or the Rational Method. AI models are based on a different valid principle—the past is a good predictor of the future.

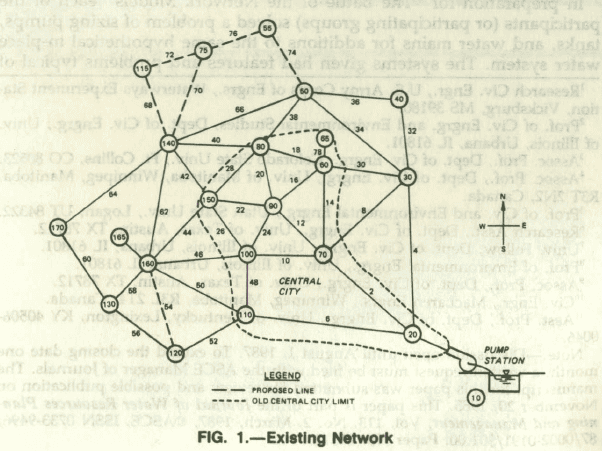

Hydraulic calculations have traditionally been based on physics-based models because we understand those principles. Yet, I’m seeing a trend where investigators are saying that they don’t need physics-based models for design and operation of hydraulic systems. And to be fair, it’s possible to find a hand-picked example, where an AI model is accurate and fast.

AI models are trained using historical data. To the extent that the problems being posed are for the same system as the training data, it is reasonable to expect that the AI model can yield good results. But hydraulic design and operational analysis usually involve answering “what if” questions and these almost always involve situations that were not encountered in the training data set. For example:

– What if we replace this pump?

– How will we respond to the fire on Adams St.?

– How will the new tank affect pumping operation?

– How will the best management practice reduce runoff?

Chances are that the AI training data does not include the new pump, or have a fire at Adams St., or include the not yet constructed tank, or have data on the new BMP. Extrapolating an AI model beyond its training data is risky at best. Addressing these issues in a well calibrated physics-based model provides confidence that the results are very likely to be accurate.

In the hands of AI professionals, with adequate data, AI models can be very valuable for predicting behaviors that can’t be modeled using physics-based models, for example, which pipe is most likely to break next?

AI professionals understand the limitations of their tools but marketing material circulating these days doesn’t always acknowledge them. As with any model, users need to understand the underlying principles, especially given that models of either type have become so complicated, that no one understands every nuance. However, understanding the basic principles behind the models, users can make the right choices in selecting their tools.

If you like blogs like this, you can go back to our library of blogs at https://blog.bentley.com/category/hydraulics-and-hydrology/.

Want to learn more from our resident water and wastewater expert? Join the Dr. Tom Walski Newsletter today!